Finished Products

Finished Products

OEM (original equipment manufacturer)

Drocco Electronic Systems produces finished electronic and electromechanical products on behalf of its clients to be sold under the client’s brand.

Our company is dynamic and eclectic, in fact we handle the entire production chain, from component and material provision to shipping packaged and labelled products.

Drocco can also assist clients during the design phase aimed at production: ODM (original design manufacturer).

In-depth Study

Analysis of the Client’s Project

Materials

Supply of electronic, plastic and mechanical components

Moulding

When required, plastic component moulding with our injection moulding machines

Assembly

Assembly of all the required components specified in the project

Our Workflow

The assembly

SMT Assembly

Specific printed circuit board production on lines which position and solder SMD components on the printed circuit.

Manual Assembly

Possible assembly on equipped manual work benches. All our dedicated staff is specialized in the field.

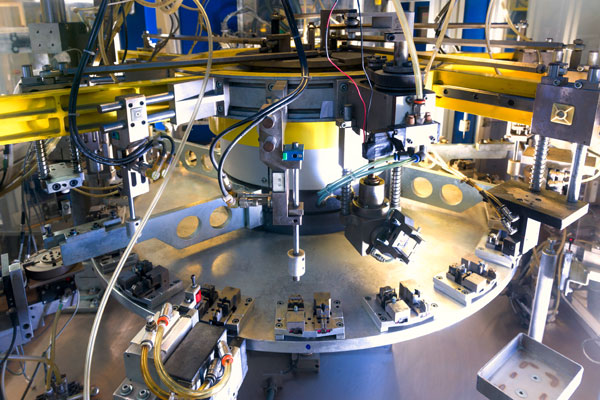

Semiautomatic Assembly

Design and Construction of Equipment for product semiautomatic mounting.

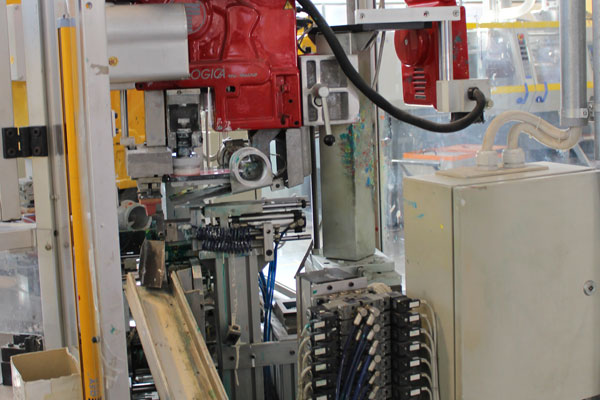

Automatic Assembly

3 types of special assembly using automatic machines: for Drocco design and construction on behalf of clients, bought by Drocco on client behalf and for client property managed by Drocco.

5. Additional Manufacture

If included in the project we perform pad printing, resin coating, ultrasound soldering, tin soldering etc.

6. Traceability

The entire production is traced and identifiable via specific assigned batches.

7. Quality Control

All tests and inspections are carried out in the Test Room under controlled temperatures.

8. Logistics

In the warehouse we package, label and ship.